PE LDPE HDPE LLDPE Film Recycling Pelletizing Line

Suitable Raw Materials

Foam film

Plastic Sheet

Garbage Bag

Swimming Pool Protective Cover

Suitable Raw Materials

Suitable Raw Materials

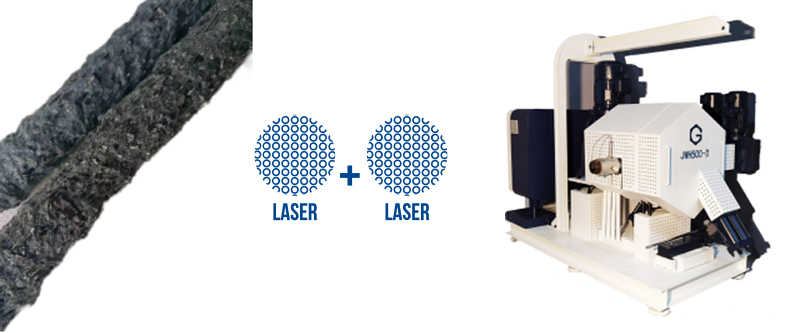

Laser screen changer (optional for post consumer ldpe film ):

Equipped with a precise temperature control and cutting system to ensure that the semi-molten plastic can quickly and stably enter the extrusion system for mixing and fusion.

The double degassing hole design of the extruder can release more ink and water vapour in the recycled material to improve the quality of the final product.

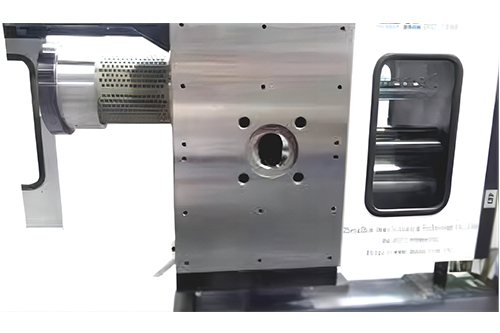

The double-column screen changing system has a filter area twice as large as the general pallet screen changing system. This screen changing system can improve filtration efficiency and reduce the number of screen changes. In addition to reducing the number of screen changes, the dual-channel design allows the machine to continue to operate during the screen change process, increasing the overall production capacity of the machine and reducing waste.

Technical data

|

model |

PTJ300 |

PTJ400-D |

PTJ500-D |

|

Filter diameter in mm |

1X300mm |

2X400mm |

2X500mm |

|

Filter area in cm2 |

575cm² |

2112cm² |

3472cm² |

|

Filtration fineness |

120-600μm 30-120Mesh |

||

|

Maximum operating pressure in bar |

250bar |

250bar |

250bar |

|

Number of heating zones |

4 |

5 |

6 |

|

Installed heating capacity in KW |

12 |

28 |

42 |

|

Engine power in KW |

3.0 |

5.5 |

11.0 |

|

Motor power discharge screw in KW |

1.5 |

2X1.5 |

2X2.2 |

|

Throughput capacity in kg/h |

300-500Kg |

500-1200Kg |

1000-2000Kg |

With two independent internal filter rooms and two independent unloading valves

Examples:

|

Processing material |

contamination |

Contamination by weight % |

Filtration fineness |

Waste contamination% |

Material losses % |

|

PE |

paper |

5 |

30-120mesh |

58-67 |

3-4 |

|

PPHDPE |

PET |

4 |

57-66 |

2-3 |

|

|

PS |

aluminum |

3-4 |

57-60 |

2-3 |

|

|

PP |

rubber, silicone |

2-3 |

55-60 |

1-2 |

|

|

PE、PP |

composite |

0.5 |

55-65 |

0.3-0.4 |

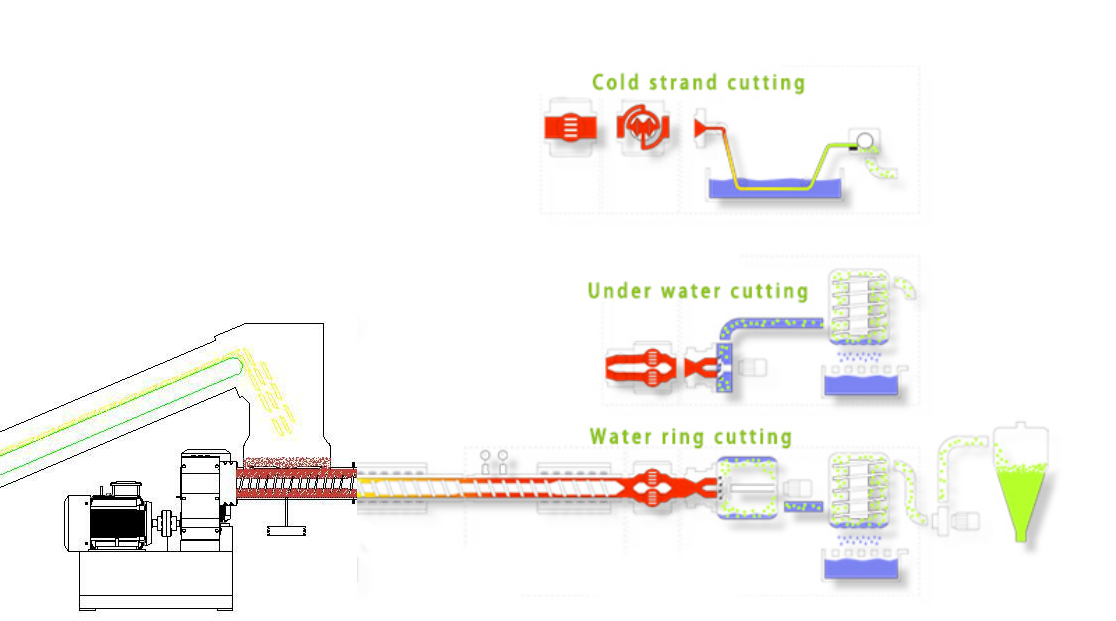

Pelletizing unit

The hot die pelletizing system can immediately pelletize the melted plastic material after extrusion. Immediately after cutting the pellets, it enters the water ring for cooling. The particle shape and size are average, conducive to re-production in various extruders and injection molding machines.

The recycled particles of the product can be 100% directly put into the film blowing machine or pipe extruder production line for reuse.

One-stop service:

Provide a complete set of solutions: factory design, equipment and auxiliary machine, fast response service system (online + underline)